High-Performance Precision Closure Mold

Product Selling Point Introduction

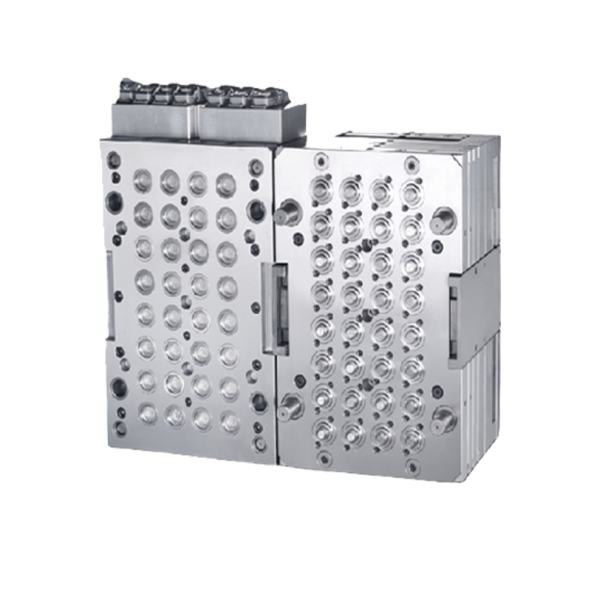

1. Our cap molding design aims to achieve short cycle times and high yields, ensuring your production line operates efficiently and meets market demands rapidly.

2. Leveraging advanced techniques and materials, our design focuses on reducing energy consumption, achieving an eco-friendly production process.

3. The mold design strives for high-density cap production to ensure product quality and appearance, enhancing brand competitiveness.

4. Our design simplifies maintenance, independent of hot runners, reducing operational costs, and enhancing equipment reliability.

5. Intelligent design ensures swift and flexible color changes, aiding you in adjusting production plans promptly to meet shifting market demands.

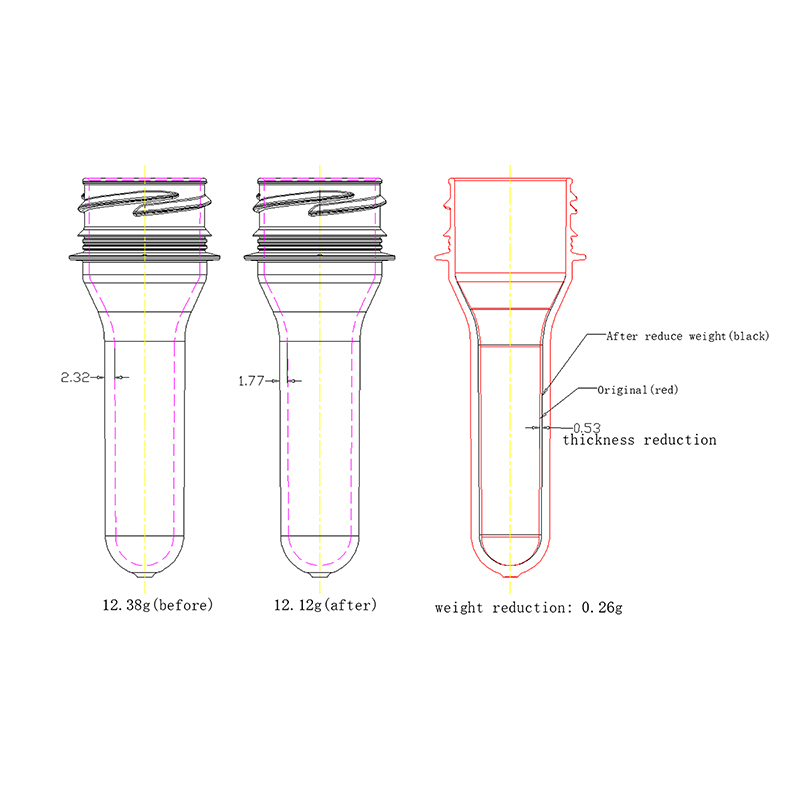

6. By minimizing waste and lowering energy consumption, our mold design achieves cost-effective production, providing you with greater profit margins and supporting business growth.

Parameter Characteristics Of The Product

| Bottle neck | 1810,1881,38mm, 29/25, 30/25 |

| Closure Types | CSD, Hot Filling, Aseptic, Flat Water |

| Life time | 10 million cycle times |

Popular Science Product Knowledge

Exploring the World of Pressure Cap Molds: Key Insights

Compression cap molds are molds used to manufacture bottle caps or lids, commonly found in the food, beverage, and cosmetics packaging industries. These molds inject molten plastic or metal material into the mold cavity under high pressure to form the desired shape.

This production process ensures the precision and consistency of the bottle caps. The design and manufacturing process of pressure cap molds require consideration of various factors, including material selection, mold structure, and temperature control. High-quality pressure cap molds can guarantee the production of caps that meet quality standards, ensuring product sealing and safety.

description2

Chinese

Chinese