Mold Holder and Frame for Rotary Blowing Mold

Product Selling Point Introduction

1. BJY has a professional design team.

2. BJY can help you testing mold holder and mold frame.

3. BJY can help you with repair old parts.

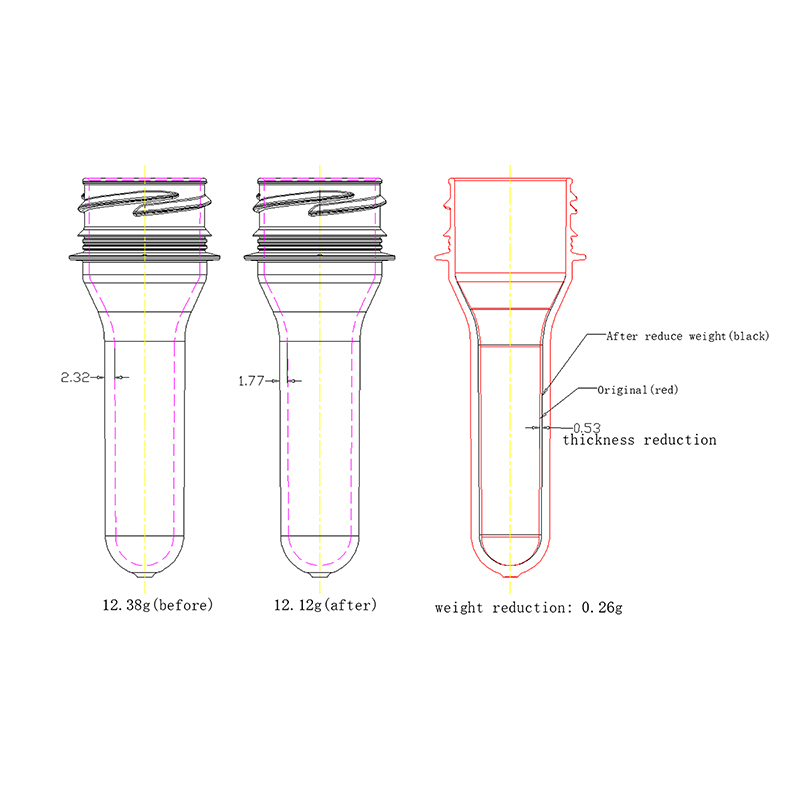

4. BJY can help you save the Money.

Parameter Characteristics Of The Product

| Equipment | Rotary Blowing Machine |

| Available Machine Brand | SIDLE, KRONES, KHS, TECH-LONG, NEWAMSTAR, etc. |

| Material | S136 for cavity, A6061 for base |

| Life-time | 10 million cycle times |

| Cavities | 6 cavities, 8 cavities, 12 cavities, 14 cavities, 24 cavities, etc. |

Including Mold Holder and Mold Frame

What is Mold Frame?

The mold frame is an important component of the blow molding machine and is crucial for producing high-quality bottles. Its main function is to support the blow molding machine mold, allowing for smooth blowing operations. The frame is forged from high-strength steel and the supports are cast from high-strength iron materials to ensure the durability and stability.

What is mold holder?

The Mold Holder mounts to the Compaction Pedestal and centers the mold over the post. The Mold Holder keeps the mold, collar and base securely positioned during compaction.

The mold frame and mold base are important parts of the rotary bottle-blowing machine. The mold frame is like a manipulator, fixed on the equipment, and its claws are used to install the mold holder.

description2

Chinese

Chinese